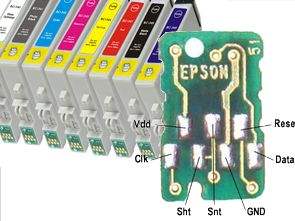

Epson Cartridge Reset Circuit

Eddie's Ink chip hack.Fighting theEpson ink chip and winning!!Or how tovoid your printer warranty on the internet.Started 22/09/02This project continues atWhat is a Intellidge ink chip.Epson fitsmall circuit boards to most of their ink cartridges. Theserecord the amount of ink that is estimated to be in thecartridge. I read that the official epson line is that it is forthe customers benefit and not an anti-refill device. Whether youbelieve this or not they are a bloody nuisance to anyone wantingto refill the cartridges or use bulk ink. It also stops peopleusing old cartridges full of solvent for cleaning the heads.Another problem was early printer models didn't check if thecartridge had been changed while power was on.

This was good ifyou wanted to trick the printer into copying a “full”chip to and empty one, however the reverse was also true and youcould easily copy and “empty” one into your fullone.They are just a small memory device holds 32 bytes ofdata, they do not measure real ink level and nor does theprinter. The printer reads the chips on startup, estimates(sometimes badly) how much ink should have been used and writesthis back at shutdown. They hold other data as well.So epsongo to the trouble of fitting chips to cartridges and building allthe extra sockets, wiring, electronics and software into theprinter so you can use the computer to see the predicted leveland it can stop you printing if it think you've used enough ink.High-end Canon's on the other hand make the inks tank clear soyou can see and have optical sensor to detect emptiness.

An Epson printer resetter comes with several options for a reset. You can reset everything from the Epson printer IP address to the entire printer system. The type of reset chosen depends on your. May 22, 2017 Suitable for Epson T29 / Strawberry Ink XP-235, XP-245, XP-247 XP-332, XP-335. How to reset an Epson ink cartridge and trick it into thinking it's full. Also Epson T18 18 18xl (Epson Daisy.

Thismake a lot more sense – unless you are making ananti-refill device that is. Canon almost got my business thistime but nobody I could find has run pigment in them – toorisky.To get around the chip problems someone usually end upproducing read-only chip which always read full (for use withCIS) and chip reseters for those who want to refill. These arenot available for 2100p at the time of writing as far as I cantell.Before ordering my 2100p I did my homework and it seemedfairly likely a chip reseter would become available at some pointand read-only chips as well. I was also cocky enough to think Icould crack it myself and I have. It didn't go quite as expectedthough.What do I want to do?I want the easiest wayto fool the printer into believing it has full cartridges presentso I can build my CIS.What did I expect?A logicalinterface for Intellidge is i2c (i squared c) or TWI (two wireinterface). Then the chip could just be some standard i2c eeprom.The Intellidge have too many pads for this but I was hopeful.After that would could SPI or microwire – again this coulduse off the shelf parts. If the chips were micro-controllers thenplain asynchronous serial would be my choice.I had alook.To do this I use a AVR mega323 micro, I declinedoffers of logic analyzers being a homebrew type of guy.

The 323has 2K of internal ram which is enough for some minimalist datalogging. It was about $50AUS in parts ($30US) to make. I wired acartridge to bring the signals out and took a quick look with avoltmeter.Nothing!There was nothing there. Iexpected some power but no, the chips are only powered brieflywhen the are accessed. I used leds to get a rough idea what waswhat and hooked up the micro via resistors to give some degree ofprotection to the printer if I screwed up.

The code in the microwas written is assembler and captured data sent via rs232 to myPC where I wrote a delphi program to display and process thedata.This is the sort of thing I got. Noprotocol I ever seen.

Obviously synchronous with bi-directionaldata, very short format. I was confused a little by how short itwas - because I expect much better precision for the inklevel.The traces seem to be.Top – some sort of syncline, this always goes low before the start of transmission.Next– power this goes low (off) between chip reads at printerstartup but stays high during the shutdown – when data iswritten to the chip.Next – the clock, data is read ofthe rising edge and changed on the falling.Bottom –bi-directional data, the first 4 bits are always from printer tothe chip, the rest depend on whether it is a read or write. LSBfirst (left).Convert to binary and some patterns emerge.Itwas not real obvious how the chips were addressed or which bitsencoded ink levels. Some more data when some ink had been usedmade it easier.Below is one chip being read at startup, thereare 7 accesses one for each chip. Only 3 block have data –the other chips must be hooked to different data lines.Below is the complete shutdown stream. Again wecan only see 3 chips from here.Afterprinting a few bits near the beginning of the bit stream didchange.

It looks to me like the first 3 bits are the chip addressthe next is a write bit then the ink level, I get the feelingthere aren't many bits used to encode it (later looks like 6).So– the top one shows 252 bits of data being read out of thechip.The first part of the shutdown shows just the ink levelbeing read out, this is to check the same chip is there.Thesecond part is the ink-level and some other stuff (printer serialnumber maybe) being written into the chip. Seeing I didn't useany ink the bit-stream is identical to the read except for bit 3– presumably the write bit.Tuesday24 Sept 2002.

I fooled the printer.Theinteresting thing about this screen grab is the black cartridgeis really only two thirds full. I spoofed the printer by pullingthe serial data line low during the time the ink level bits arebeing clocked out of the ink chip.This is means 6 bitsstarting at the 5'th bit in the stream.The first 3 bits appear to be thechip address, I guess the next is a read/write select. I used aAVR mega323 to detect the start of the serial transmission lookfor the address of chip1+read (black apparently) then pull datalow for 6 clock edges.I'm sure I can reset 3 of the chipsby tapping into chip1 signal. Reseting the rest will mean tappinginto at least one more.The current set up is forexperimentation only – it is not “the real thing”.Shorting the data to ground may be abit drastic but it is only for a very brief time.

Epson Ink Cartridge Resetter

I hoped thedata line would be open collector but this doesn't seem to be thecase.Tuesday1'st October. reading the chip without the printer.Idon't really need to do this but I wanted to see if I reallyunderstood the protocol. I wrote code for the micro to act as amaster for the chip. I knew the chip was a low voltage part but Ihoped it would be 5 volt tolerant and save me some trouble.

Epson Cartridge Reset Software

Aftergetting no sense out of two chips and confirming the printer couldn'tread them either I assume I've killed them. I went shopping andbought 3V3 zeners and 330R resistors to limit the output of the microport to 3V3. Data started to flow. The micro would not read itbecause is was below the input threshold so I added a pull up to thedata pin (on the micro side of the 330R current limiting resistors sothe inkchip didn't see 5V). I could then read the contents of thechip.Ithen spent the afternoon trying to write to it without any success.Wednesday2'nd October – reseting the chip without the printer.Aftersleeping on it, I wrote a better trigger routine for my data-loggingprogram so I could get a better look at what the printer diddifferently.

The trace revealed all.Whatyou see here is the printer starting a write sequence at normal speedthen after transmitting the address and write bit the clock (2'ndfrom bottom) slowed down to around 1 Khz. I wrote a “slowwrite” routine and presto I can write to it. My code simplywrites zeros to the first 8 bits in the chip. I repeat the process 7timse using every chip address.

The proof was to take an emptycartridge - zap it and feed it to the printer. The printer said yumand did it's charging thing - then showed a full cartridge on thestatus monitor. Descargar de mega con idm.

I won't bore you with another image of it. A chipreseter could be made with a $2 micro and not much else – thesocket is a problem. Most people can't program micros but for thosewho can it is trivial now that the protocol is knonw. My hacked aboutcode is too ugly to show here.Alan Chan has sent me this hoping it would helppeople ID their chips.